Creation Time:2025/7/28

Paper plastic packaging bag, also known as sterilization packaging bag

1、 Advantages

1. Good moisture resistance: The inner layer of paper plastic packaging bags is formed with a thin film due to the excellent fluidity and film-forming properties of PVA (polyvinyl alcohol), which combines composite bonding and moisture resistance during pressure lamination; At the same time, the fine pores on the surface of the material can effectively block external water molecules from entering the package, preventing internal items from getting damp.

It has been widely used in the medical field. Let's take a look together

What is paper plastic packaging bag?

Paper plastic packaging bags are usually composed of two different materials, one layer is a paper material that can pass through and discharge sterilization factors, and the other layer is a transparent composite film (plastic film) with liquid, air, and gas barrier properties.

During the sterilization process, the exchange of air disinfection factors is only completed on one side of the paper material. Thanks to the material properties, the packaging bag also has a reliable microbial barrier function; On one side of the transparent plastic film, the contents of the bag can be clearly observed, which not only realizes the visualization of the contents, but also gives the packaging bag excellent anti-seepage ability.

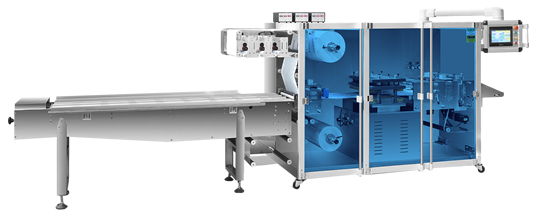

What kind of equipment needs to be packaged in paper or plastic bags?

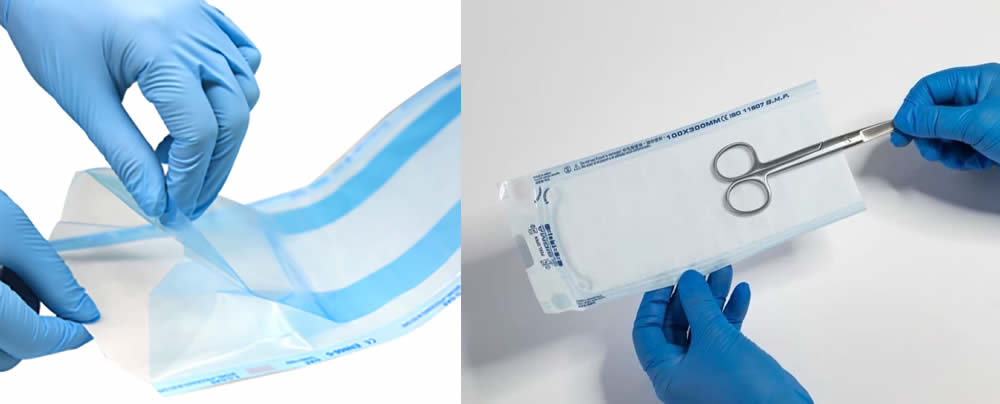

For instruments that require separate use and are lightweight, paper plastic bags are a commonly used packaging option. This packaging method not only allows users to visually observe the color change status of the indicator card, but also allows them to clearly view the style and model of the instrument through the transparent surface, making it convenient for surgical personnel to quickly identify and retrieve it for use.

What are the requirements for paper plastic bag packaging?

1. Sealed packaging often uses heat sealing technology and requires the use of packaging materials that are compatible with the size for plastic sealing. Among them, the sealing width at the sealing point must be ≥ 6mm, and the distance between the instruments inside the package and the sealing of the packaging bag must be ≥ 2.5cm; if the instruments are too close to the sealing, the sealing is prone to rupture during sterilization, and if the packaging material is too large, it may cause damage to the packaging bag due to internal instrument displacement.

Before packaging, it is necessary to check the cleanliness and dryness of the items to be packaged - during high-pressure steam sterilization, if the equipment is not thoroughly cleaned and dried, residual oil and moisture can easily wet the packaging paper, causing wet packaging problems. At the same time, the tip of sharp instruments such as scissors should be protected by covering them with instrument protection sleeves or silicone tubes to prevent them from puncturing the paper plastic packaging and affecting the sterilization effect.

How to ensure the quality of paper plastic sealing and packaging sealing?

When sealing paper plastic packaging, the appropriate temperature should be selected based on the material characteristics of the packaging bag, usually divided into two categories: low temperature of 120 ℃ and high temperature of 180 ℃. Among them, the packaging of instruments used for high-pressure steam sterilization needs to be sealed at a temperature of 180 ℃ - too high a temperature can easily cause the paper plastic material to melt, while too low a temperature can cause the seal to be loose, both of which affect the packaging effect. In addition, the sealing width of paper plastic packaging bags should be ≥ 6mm to ensure the tightness of the seal and avoid the occurrence of bursting and cracking during the sterilization and vacuuming process.

Advantages and disadvantages of paper plastic packaging bags

2. Good high temperature resistance: Its strength is mainly controlled by the warp and weft structure, and the water-soluble yarn of vinylon has the characteristic of unchanged breaking force at 180 ℃. In addition, the ignition point of the paper at 183 ℃ makes the composite paper plastic packaging bag resistant to higher temperatures and suitable for sterilization needs.

3. Strong anti-aging ability: the paper itself is made of plant materials that are not easy to age, and the paper inside and outside the paper plastic packaging bag can isolate ultraviolet radiation, so as to avoid accelerated aging of materials due to light and extend the service life of the packaging bag.

4. High strength: Relying on the structural support in the warp and weft directions, combined with the triangular mesh structure formed on the outer surface of the inner paper when the weft disc rotates counterclockwise, the internal stress of the packaging bag is greatly increased, making it have high load-bearing and anti damage capabilities.

5. Excellent anti slip effect: During the pressure composite process, a triangular mesh structure is formed on the outer surface of the packaging bag, which increases the surface friction coefficient and makes it less likely to slip during stacking.

6. Environmentally friendly: Vinylon water-soluble yarn has not undergone resin formaldehyde treatment and can dissolve in hot water at 80 ℃ to form a gel solution; After soaking, the inner and outer paper of the packaging bag can be recycled and processed into recycled paper, which will not cause pollution to the environment.

2、 Disadvantages

The spare paper plastic sterile bags stored in clinical departments are prone to wrinkles and cracked seals; When packaging hard items, the dryness is poor, and some may have water droplets stuck on the inner plastic surface; Sharp instruments are also prone to puncturing paper and plastic packaging, affecting sterilization effectiveness.

According to the relevant regulations in 2009, paper plastic packaging bags are only suitable for packaging individual instruments, while flat tape is recommended for items with a thickness not exceeding 5cm. Although it is currently a widely used packaging product in hospitals, due to its single-sided breathability, metal instruments are prone to condensation during sterilization, and paper plastic packaging bags are not suitable

After-sales Service

After-sales Service

Technical Support

Technical Support

Download Center

Download Center