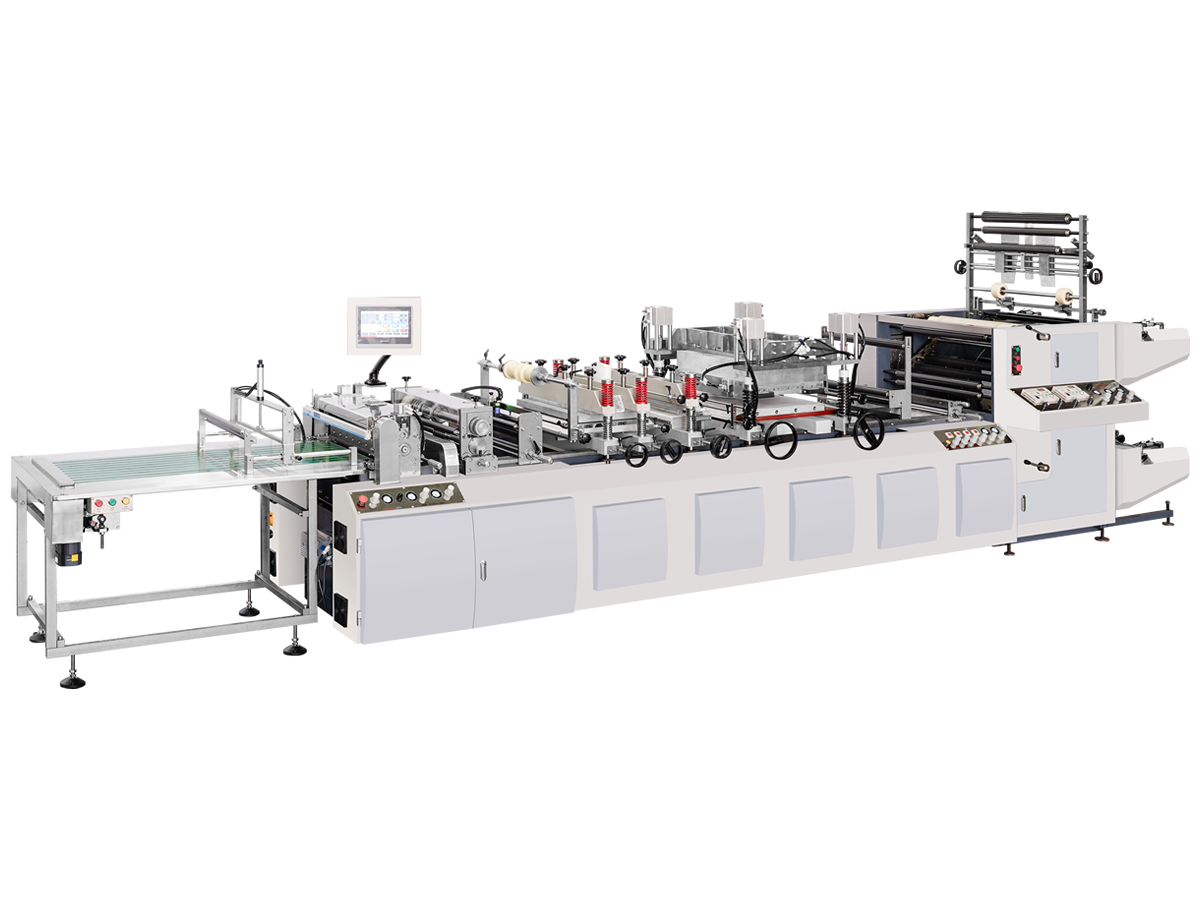

Main performance:

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine.

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine.

The host adopts servo motor with driver and reducer, closed-loop precise control, real-time correction of deviation, and adjustable hot pressing time.

The host adopts servo motor with driver and reducer, closed-loop precise control, real-time correction of deviation, and adjustable hot pressing time.

Adopting imported servo motors and fixed length photoelectric control.

Adopting imported servo motors and fixed length photoelectric control.

Digital pressure control for hot pressing makes products smoother and improves yield.

Digital pressure control for hot pressing makes products smoother and improves yield.

The latest pneumatic locking dual discharge device, automatic correction and tension, dual discharge adopts tension control to ensure the smoothness of material pulling.

The latest pneumatic locking dual discharge device, automatic correction and tension, dual discharge adopts tension control to ensure the smoothness of material pulling.

The tension floating roller adopts a dynamic compensation mode, which minimizes the up and down fluctuations during the material pulling process and stabilizes the tension control in the middle.

The tension floating roller adopts a dynamic compensation mode, which minimizes the up and down fluctuations during the material pulling process and stabilizes the tension control in the middle.

Equipped with a quick mold changing device, efficient and convenient. Equipped with a separate horizontal sealing hot plate, it can use the double delivery function to increase the bag length by multiple times.

Equipped with a quick mold changing device, efficient and convenient. Equipped with a separate horizontal sealing hot plate, it can use the double delivery function to increase the bag length by multiple times.

Equipped with an automatic punching device.

Equipped with an automatic punching device.

Main technical parameters:

|

Maximum width of bag making |

600mm |

|

Maximum length of bag making |

500mm |

|

Number of bag rows |

1~5rows |

|

Maximum diameter of coil material |

600mm |

|

Maximum mechanical speed |

200 Strokes/Min |

|

Power supply |

380v/50Hz |

|

Total power |

40KW |

|

Overall dimensions |

6800*1530*1910mm(L*W*H) |

|

Machine weight |

About 3200Kg |

Video: