Main performance:

Adopting imported high-end PLC control and touch screen operation, all parameters can be adjusted on the touch screen.

Adopting imported high-end PLC control and touch screen operation, all parameters can be adjusted on the touch screen.

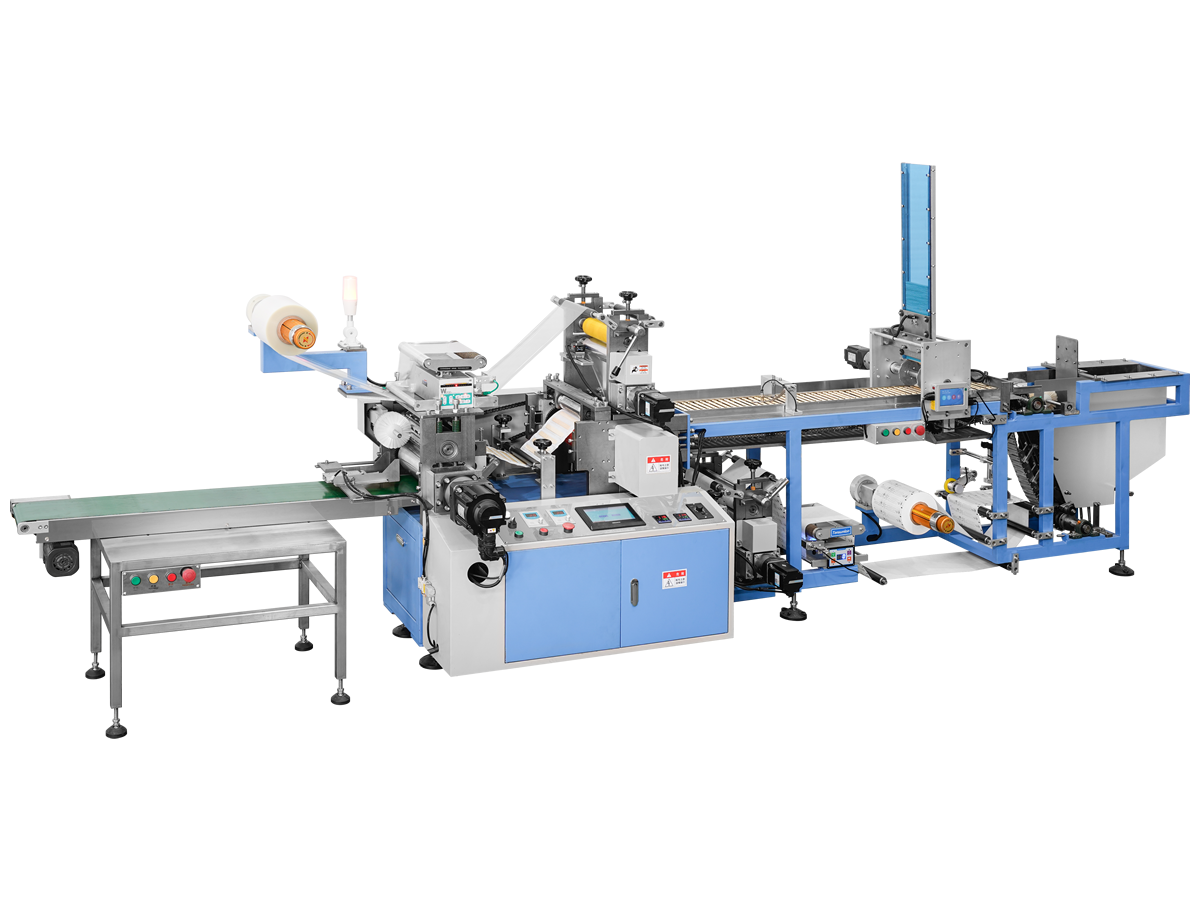

The overall structure adopts an open layout, with a modular design for good visibility of workstations and easy maintenance and adjustment.

The overall structure adopts an open layout, with a modular design for good visibility of workstations and easy maintenance and adjustment.

The overall structure adopts an open layout, with a modular design for good visibility of workstations and easy maintenance and adjustment.

The overall structure adopts an open layout, with a modular design for good visibility of workstations and easy maintenance and adjustment.

Adopting servo driven gearbox transmission, the upper and lower knife rollers are matched with dual heating heat sealing to ensure the heat sealing pressure of the packaging material, as well as to ensure that the packaged products are not breathable and leak sealed.

Adopting servo driven gearbox transmission, the upper and lower knife rollers are matched with dual heating heat sealing to ensure the heat sealing pressure of the packaging material, as well as to ensure that the packaged products are not breathable and leak sealed.

Roll film mechanical feeding and forming bag making, color matching photoelectric mechanism, capable of matching printed graphics and text.

Roll film mechanical feeding and forming bag making, color matching photoelectric mechanism, capable of matching printed graphics and text.

Equipped with double-sided printing tracking, it can produce double-sided printing products.

Equipped with double-sided printing tracking, it can produce double-sided printing products.

The enlarged roll film feeding platform and film roll can reach a maximum diameter of 400, reducing equipment downtime and increasing overall practicality of the equipment.

The enlarged roll film feeding platform and film roll can reach a maximum diameter of 400, reducing equipment downtime and increasing overall practicality of the equipment.

Equipped with an automatic replenishment rack to detect vacancies and automatically replenish them.

Equipped with an automatic replenishment rack to detect vacancies and automatically replenish them.

The finished product conveyor belt outputs and receives materials in sequence.

The finished product conveyor belt outputs and receives materials in sequence.

Main technical parameters:

|

Maximum mechanical speed |

500 packs/minute |

|

Specification of tongue depressor plate |

150*18mm |

|

Packaging bag specifications |

190*35.56mm |

|

Roll width |

190-195mm |

|

Maximum diameter for loading materials |

≤450mm |

|

Maximum diameter of material discharge |

≤450mm |

|

Voltage |

380v/50Hz |

|

Overall dimensions |

4600x960x1750mm |

|

Total weight |

约800Kg |

Production sample:

Video: