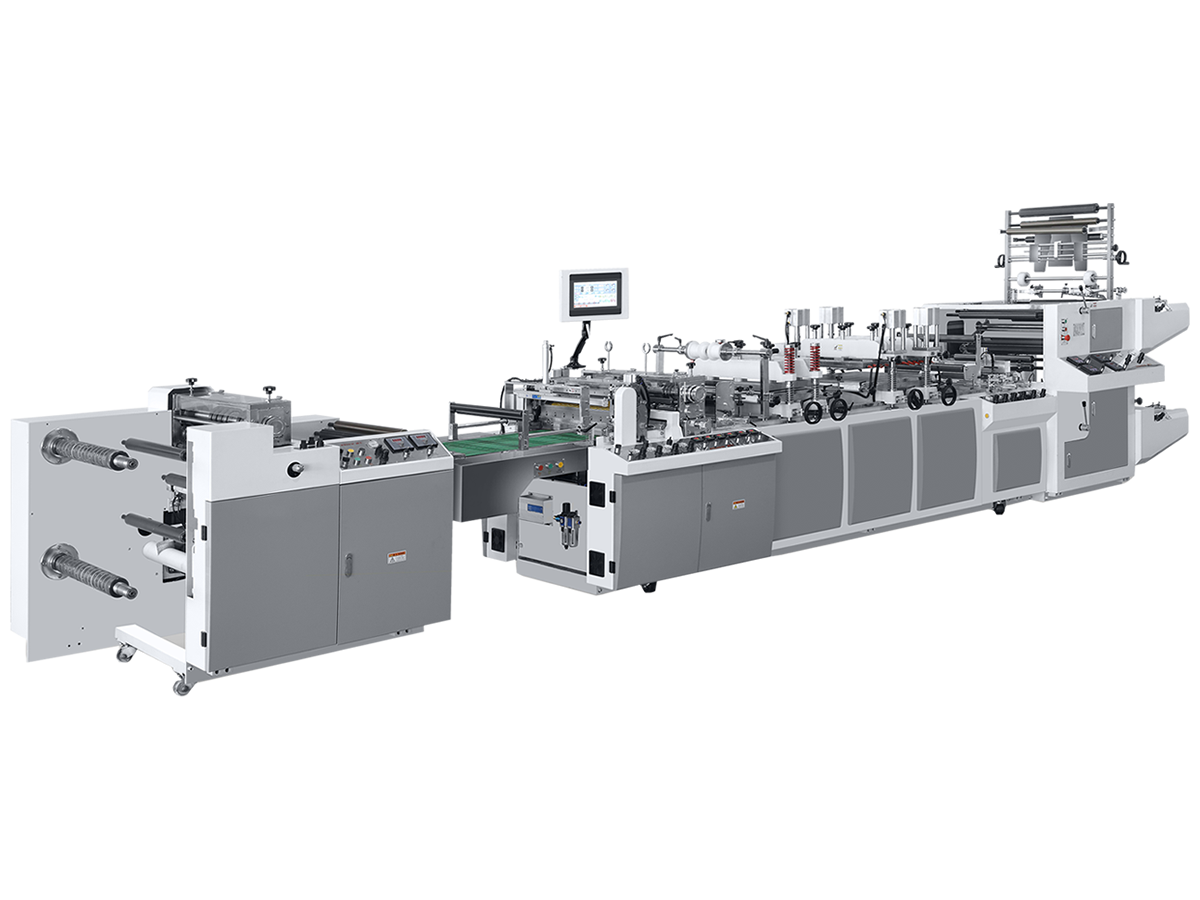

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine.

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine. The discharge traction adopts imported servo motors, and the finished product discharge department can achieve two production modes: tube bag and bag cutting, with easy switching.

The discharge traction adopts imported servo motors, and the finished product discharge department can achieve two production modes: tube bag and bag cutting, with easy switching. During bag cutting production, fixed length photoelectric control is used, equipped with an automatic punching device.

During bag cutting production, fixed length photoelectric control is used, equipped with an automatic punching device. Double position winding is used in the production of tube bags. The winding motor is controlled by a frequency converter, and the winding tension is controlled to ensure that the tension of each sub roll is uniform and the winding end face is neat.

Double position winding is used in the production of tube bags. The winding motor is controlled by a frequency converter, and the winding tension is controlled to ensure that the tension of each sub roll is uniform and the winding end face is neat. The host adopts imported variable frequency speed regulation.

The host adopts imported variable frequency speed regulation. Digital precision pressure control ensures smoother products and improves yield.

Digital precision pressure control ensures smoother products and improves yield. The new pneumatic locking dual station dual discharge device is equipped with dual automatic correction dual magnetic powder tension, dual frequency conversion feeding is stable and reliable, and the pneumatic expansion shaft feeding is fast and convenient.

The new pneumatic locking dual station dual discharge device is equipped with dual automatic correction dual magnetic powder tension, dual frequency conversion feeding is stable and reliable, and the pneumatic expansion shaft feeding is fast and convenient. Equipped with an automatic punching device.

Equipped with an automatic punching device.

Double sided adhesive packaging.

Double sided adhesive packaging.

Main Features:

Main technical parameters:

|

Maximum width of bag making |

600mm |

|

Maximum length of bag making |

600mm |

|

Number of bag rows |

1~5rows |

|

Maximum diameter of coil material |

600mm |

|

Maximum mechanical speed |

150 Strokes/Min |

|

Power supply |

380v |

|

Total power |

22KW |

|

Overall dimensions |

6500*1530*1910mm(L*W*H) |

|

Machine weight |

About 3000Kg |

Production sample:

Video: