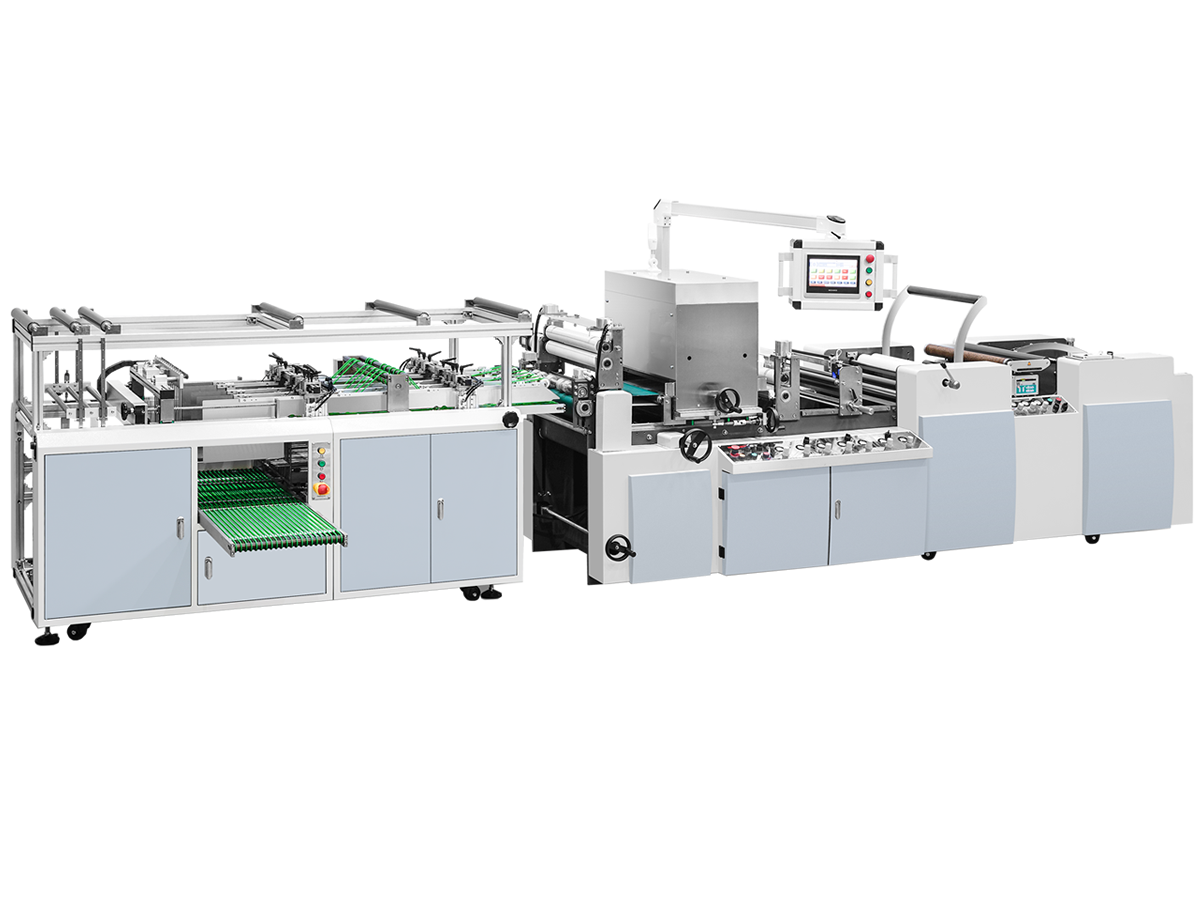

Main performance:

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine.

Adopting PLC servo control and operating system, human-machine interface touch screen system provides precise guarantee for the high-speed and stable operation of the machine.

Micro adjustment of die-cutting torque greatly improves the service life of cutting tools.

Micro adjustment of die-cutting torque greatly improves the service life of cutting tools.

Touchscreen one click knife loading, fast and convenient, greatly saving operation time.

Touchscreen one click knife loading, fast and convenient, greatly saving operation time.

Equipped with automatic waste winding function, waste winding is centrally processed without the need for manual cleaning.

Equipped with automatic waste winding function, waste winding is centrally processed without the need for manual cleaning.

Die cutting is completed, and the sheet materials are automatically collected and sorted, counted and stacked, greatly reducing the waste of time and manpower.

Die cutting is completed, and the sheet materials are automatically collected and sorted, counted and stacked, greatly reducing the waste of time and manpower.

Automatic die-cutting of various shaped products, with a wide range of applications.

Automatic die-cutting of various shaped products, with a wide range of applications.

Finished product transportation is equipped with batching and counting functions.

Finished product transportation is equipped with batching and counting functions.

Main technical parameters:

Maximum mechanical speed

200Cut/Min

Maximum die-cutting size

600*400mm(L*W)

Roll width

610mm

Maximum diameter of coil material

1200mm

Maximum weight of coil material

250kg

Overall dimensions

5960*1930*1800mm(L*W*H)

Power supply

380v/50Hz

Power

约11KW

Total weight

约2000Kg

Production sample: